When you need a dental crown or bridge, your dentist works with a specialized dental lab to create a custom restoration that fits seamlessly and functions like a natural tooth. But how exactly are these prosthetics made? Here’s a behind-the-scenes look at the precision-driven process that ensures durability, aesthetics, and comfort.

Step 1: Digital Impressions & 3D Design

Your dentist takes a digital scan (or traditional mold) of your teeth.

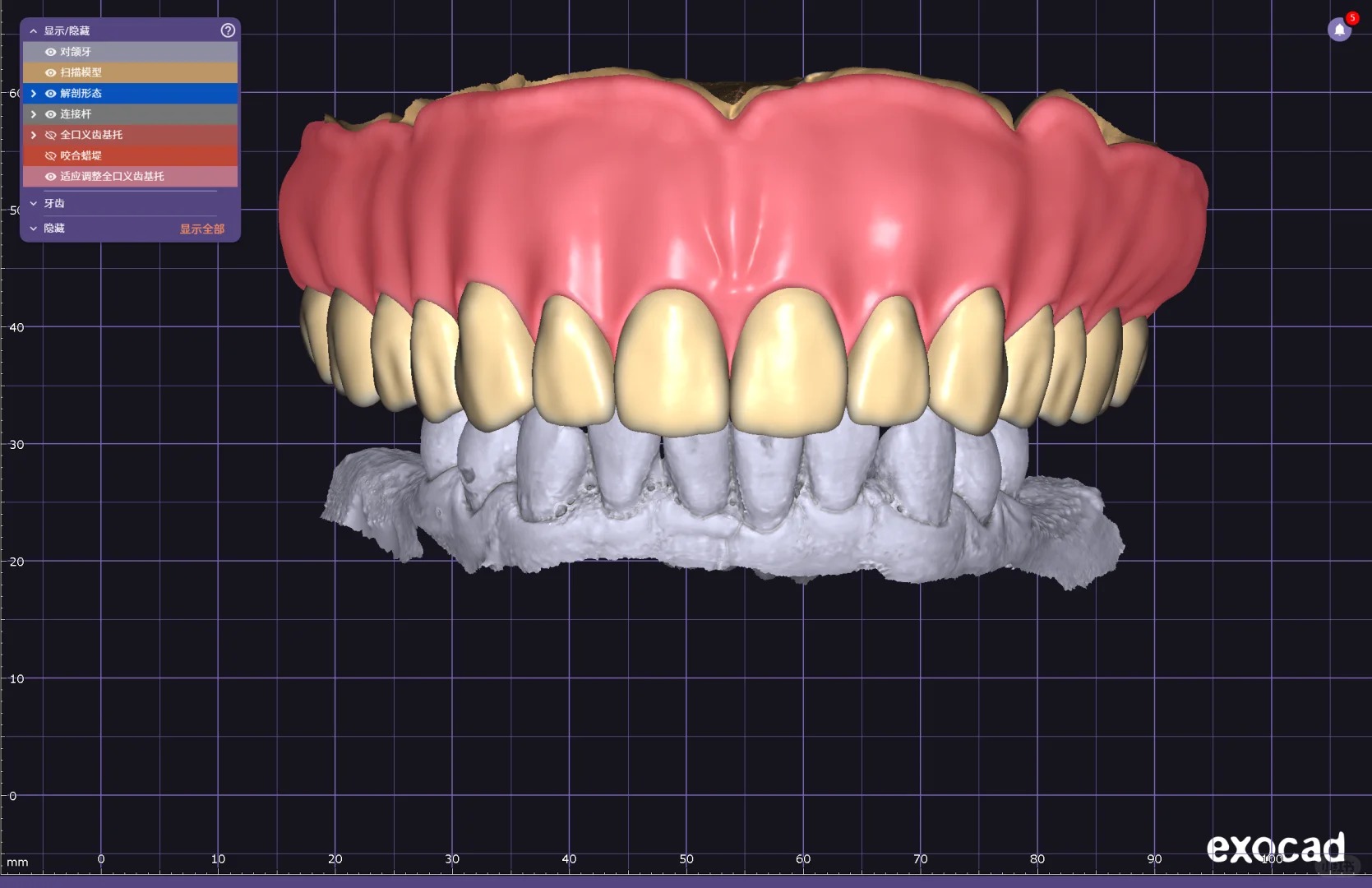

The lab uses CAD/CAM (Computer-Aided Design & Manufacturing) to create a 3D model for a perfect fit.

Advanced software ensures proper bite alignment and natural-looking contours.

Step 2: Material Selection – Strength & Aesthetics

Metal-ceramic (PFM): Durable with a natural tooth-colored coating.

All-ceramic (Zirconia/E.max): Highly aesthetic, metal-free option.

Gold alloy: Long-lasting, ideal for back teeth.

Step 3: Milling & Layering for Lifelike Appearance

A high-precision CNC machine mills the crown/bridge from a solid block of ceramic or zirconia.

For porcelain-fused restorations, technicians hand-layer ceramic to mimic natural translucency and shading.

Step 4: Firing & Polishing

The restoration is fired in a kiln to strengthen the material.

Expert technicians polish it to a smooth, glossy finish, preventing plaque buildup.

Step 5: Quality Check & Delivery

The lab verifies fit, color match, and function before sending it to your dentist.

Your dentist then bonds it permanently, ensuring a secure, long-lasting result.

Why Choose a Professional Dental Lab?

✔ Custom-fit – No “one-size-fits-all” solutions.

✔ High-quality materials – No cheap, brittle alternatives.

✔ Advanced technology – Digital accuracy for better comfort.

✔ Durability – Properly made crowns/bridges last 10-15+ years.

Need a Crown or Bridge? Visit globaldenture.com for precision-crafted, affordable dental restorations!